|

|

|

|

|

| Bacteria Detection: microbial control practices are often based on an incomplete, or even wrong approach. Commonly, several efforts are spent to monitor free-floating bacteria in the liquid. Even if this is a widely-applied standard, it does not keep into account biofilm. |

|

Bacterial contamination in Food & Beverage: accurate methods for the early detection of bacterial growth are necessary, to evaluate the need and effectiveness of sanitation treatments, to avoid contamination, and to ensure food safety. |

|

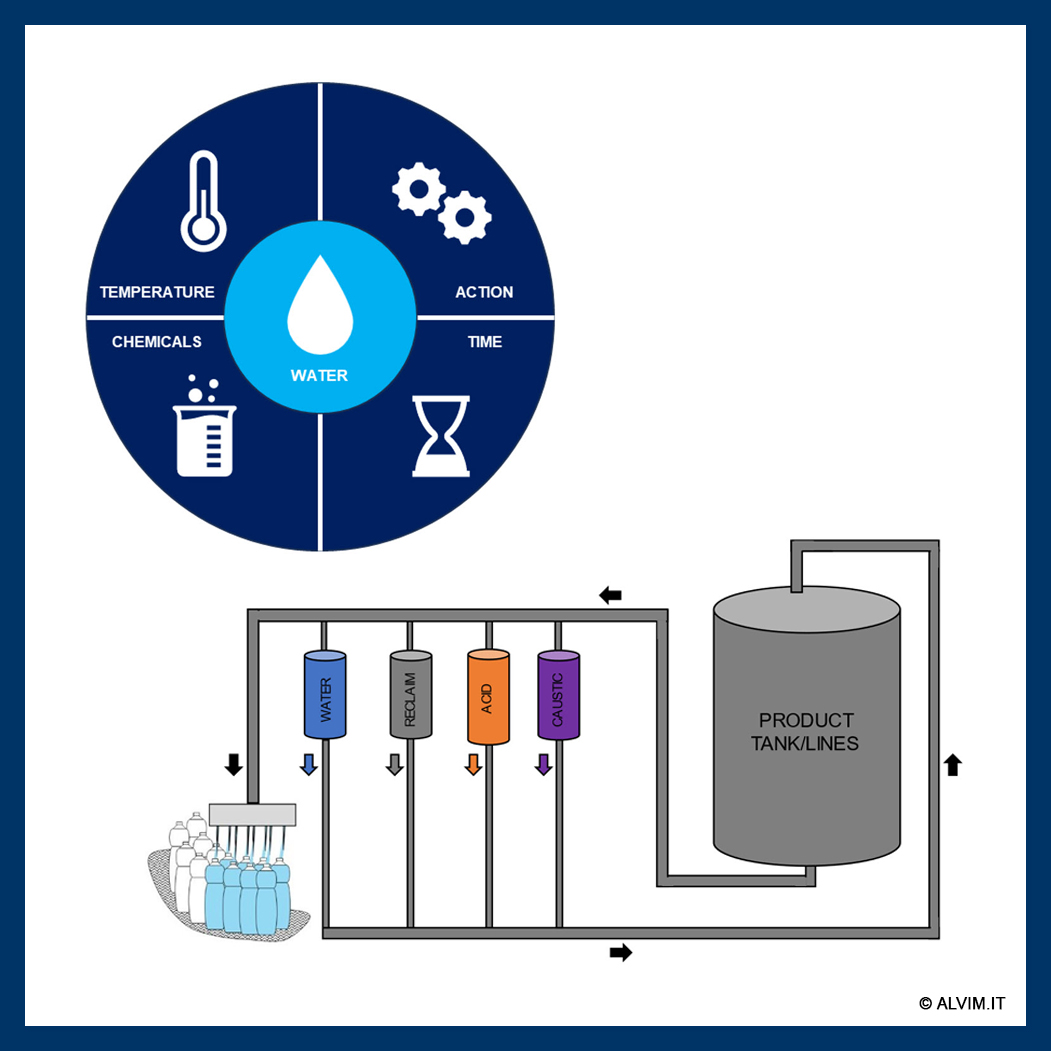

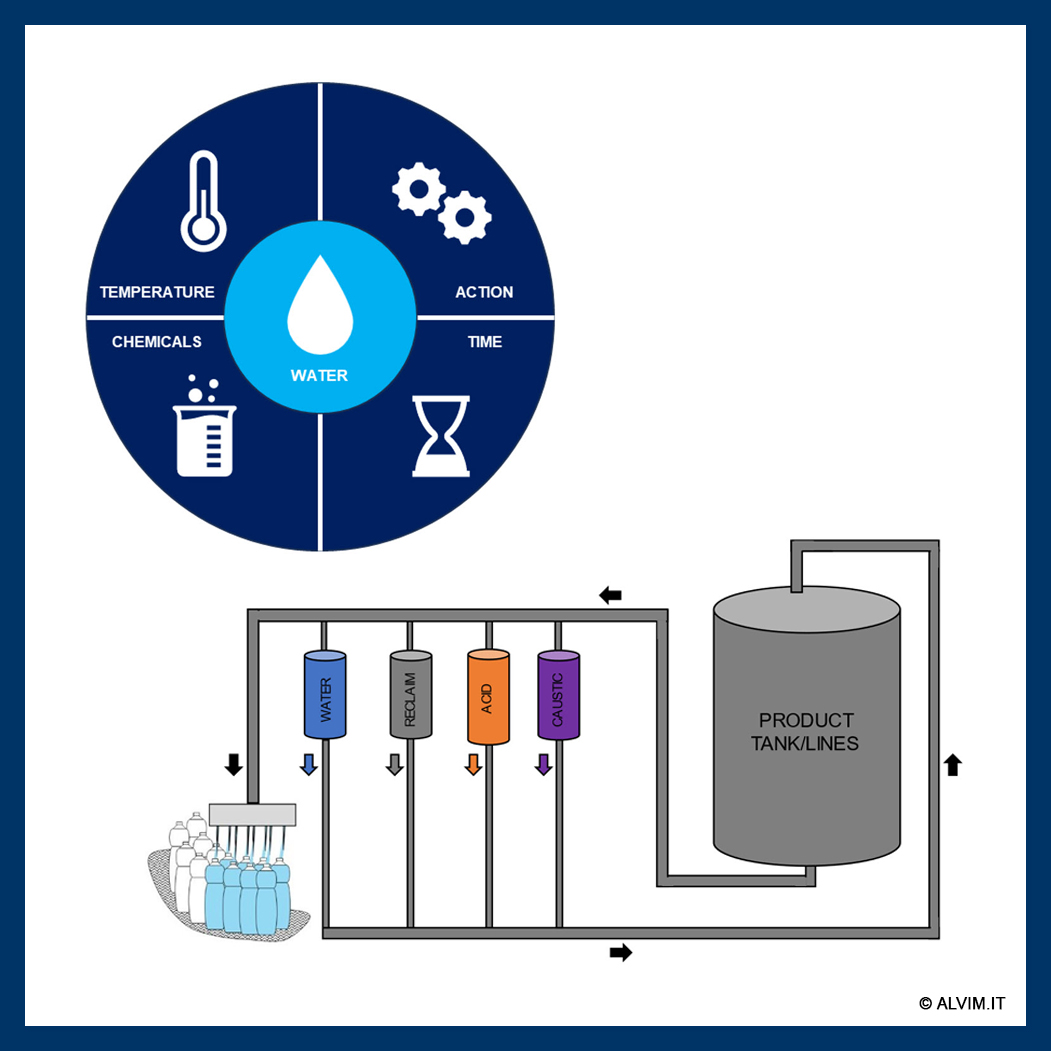

Clean in Place: the quality of the final product in many industries is directly linked to the effectiveness of the cleaning process and, consequently, the presence or absence of microorganisms. One of the most practical and widely used methods for cleaning closed processing systems is Clean in Place (CIP). |

|

|

|

|

|

| Frozen food: although the main purpose of freezing is to preserve the quality of food with excellent results, this process also preserves the viability of some pathogenic microorganisms. |

|

HACCP and Biofilm: biofilm monitoring approach is an integral part of a modern process control system known as Hazard Analysis and Critical Control Points (HACCP). This internationally regulated approach, which is based on scientific principles, aims at safeguarding food from biological, chemical and physical hazards. |

|

Fluctuations in Bacterial Count: to monitor the bacterial contamination of a process, sampling and laboratory analysis of the liquid represent the most common approach This allows to detect free-floating microorganisms - and it happens quite often to observe large and unexpected fluctuations in the amount of bacteria in the sample. |

|

|

|

|

|

| Biocides: the selection of a suitable biocide for a specific application is not sufficient to guarantee optimal results against bacteria. In order to keep pipelines clean, prevent problems, save money and time, it is necessary to check the real efficiency and to optimize the treatment. |

|

Oxidizing and non-oxidizing biocides: the choice of a sanitation treatment must be specific for each application, since the effectiveness of a biocide depends on many system variables. Some disinfection programs combine oxidizing and non-oxidizing biocides, to exploit the best of both. |

|

Residual chlorine: monitoring microbial contamination in pipelines, and assessing the effect of biocide treatment is important - doing it correctly is crucial. Unfortunately, residual chlorine measurement does not provide a full understanding of the results of sanitation, nor of the amount of bacteria in the pipeline. |

|

|

|

|

|

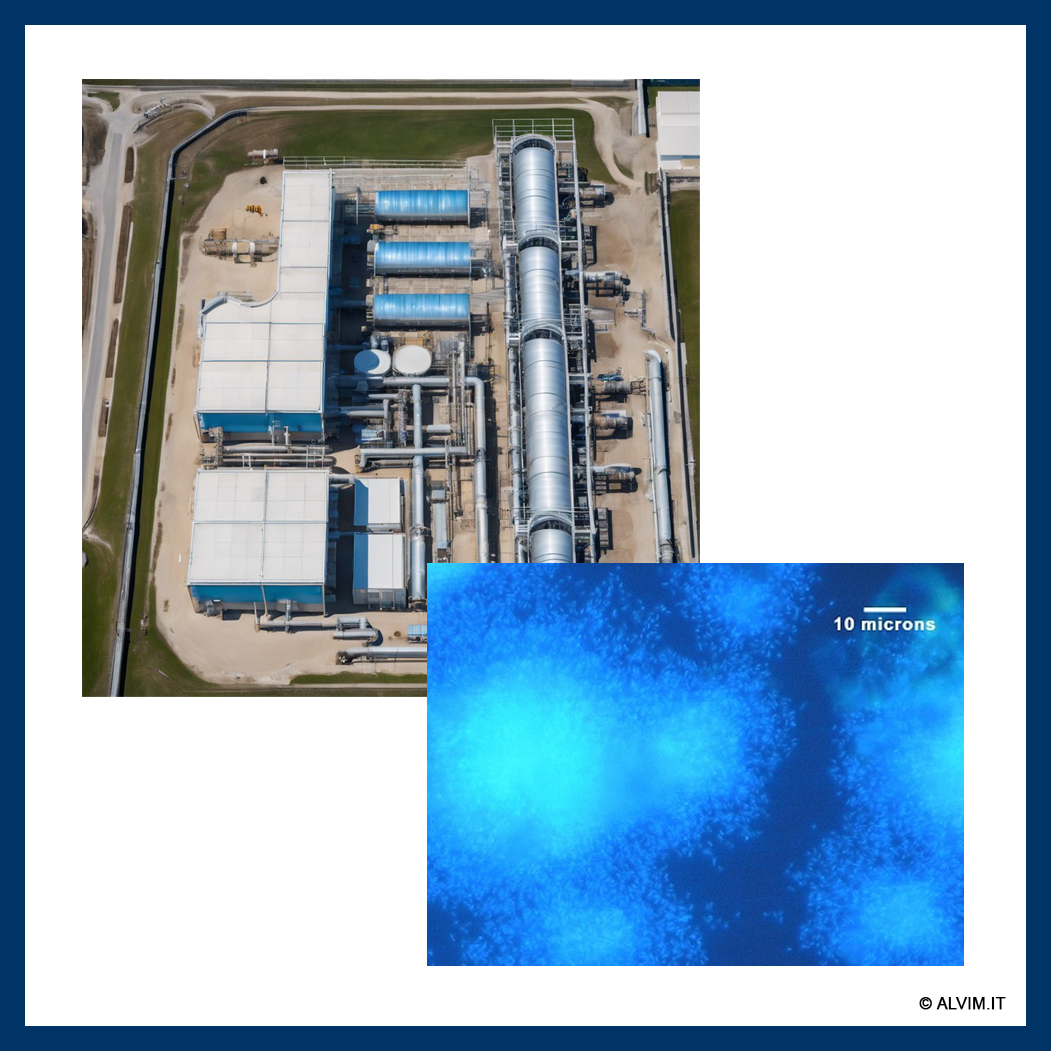

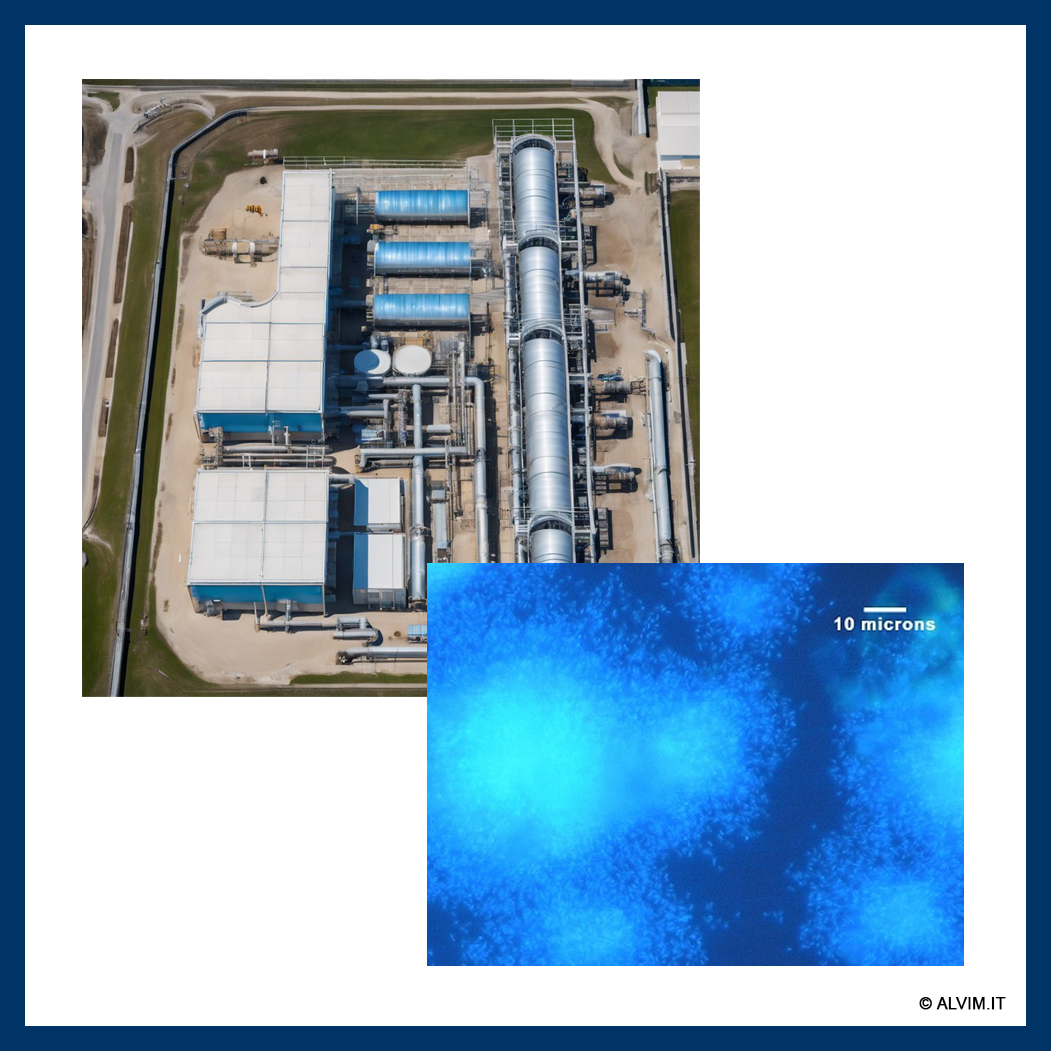

| Biocide optimization in Oil&Gas water treatment: oil and natural gas are key industries in the energy market, and they play a dominant role in the global economy. Huge amounts of water are used for different purposes, especially in upstream operations, and chemical biocides are commonly dosed to limit microbial proliferation. |

|

Biofilm & Energy efficiency: the improvement of energy efficiency within the industrial sector is, currently, a hot topic at global level. Unfortunately, the impact of biofilm growth on energy use and efficiency is frequently underestimated. |

|

Safe Water in Smart Cities: both human and environmental health are strongly dependent on the preservation of water. In order to ensure it, monitoring technologies play an important role. Indeed, the application of smart technologies allows to optimize water treatment and to preserve this precious resource. |

|

|

|

|

|

| Cooling towers: although their process is effective in removing heat, it also causes serious sanitation and contamination concerns. Indeed, pathogenic bacteria that survive and proliferate in this environment can easily spread with aerosol, even for kilometers. |

|

Biofouling in membrane processes: a major obstacle for the application of membrane is the loss of efficiency over time, due to fouling. Microorganism adhere to the membrane blocking the pores, forming the so-called “biofouling” or “microfouling”. |

|

Pretreatment in desalination process: desalination has become an essential solution for addressing water scarcity in various regions worldwide. Biofouling can significantly impact the efficiency of this process, by reducing water flow, increasing operational pressure, and elevating energy consumption. |

|

|

|

|

|

| Poultry Water Treatment: in poultry farms, the presence of bacteria is ubiquitous and this can cause the growth of unhealthy animals, with impact on human health. Maintaining drinking water quality is essential for poultry health and plays a key role to achieve optimal flock performance. |

|

Legionella prevention: L. pneumophila is commonly found in spring waters, thermal waters, rivers, lakes and sludge. From natural environments, it easily reaches building water systems, water tanks, pipes, fountains and pools, that can act as incubators for this microorganism, creating a potentially hazard condition for human health. |

|

Drinking water distribution systems: the protection and maintenance of water distribution systems are essential to ensuring high-quality drinking water. Recent data on waterborne disease outbreaks suggest that distribution systems remain a source of contamination that has yet to be fully overcome. |

| |

|

|

|

|

| |

|

Return On Investment of Biofilm Monitoring: the industry is investing many resources in the optimization of production and processes, also with "Industry 4.0" initiative. For what concerns cleaning and sanitation treatments, biofilm monitoring can greatly increase efficiency, with a fast ROI. |

|

|