Frozen food [Download this white paper as PDF file]

Freezing is an ancient technique, known since the Middle Ages, that allows to preserve food for longer lowering its temperature. The use of this method at an industrial level had a great development in the 20th century. Nowadays, the frozen food market is one of the most important sectors in the food industry, and it is estimated to reach a turnover of 300 billion dollars in the next few years. The main reason for this increase is that the demand and consumption of frozen food around the world is linked to the globalization and the hectic lifestyle of population, thus making frozen products increasingly convenient to consume.

Freezing products is an excellent strategy for preserving a high quality - thanks to it the taste, texture and nutritional value of foods are maintained.

The quality of frozen foods is critical and it depends on careful pre-freezing preparation, control of freezing process and post-freezing handling of the product. To obtain high-quality frozen foods, high quality raw materials are necessary. In terms of freezing operations, the primary objective is to maintain as much of the original and characteristic product quality as possible. Once frozen, the product must be transported with appropriate means and techniques to preserve its quality. This is where the "Cold Chain" comes into play. The cold chain is made up of a series of techniques that guarantee the highest quality of the product, from production to transport, down to sale.

The most commonly used storage temperature, to stop the growth of microorganisms and thus to preserve food safety, is -18 °C. At this temperature, only a part of the bacteria originally present in the food is permanently inactivated, while the majority of microorganisms is still alive, waiting for better conditions to start multiplying again. This favorable time is represented by defrosting - indeed, if this procedure is not carried out properly and the food is not immediately used, risks to human health may occur.

At an industrial level, several freezing methods are available, mainly based on two principles:

1. The maintenance of very low temperatures to inhibit the growth of microorganisms and limit their chemical-enzymatic activity. Temperature is an important factor for microbial growth. Each species of bacteria has its own optimal temperature for growth. Low temperatures usually inhibit or stop microbial growth and proliferation, but often do not kill bacteria. Indeed, in a cold environment enzymes function is slower, because of the reduction in the movement of molecules, that leads to fewer collisions between the enzymes and substrates.

2. The formation of ice crystals that removes water from food, preventing the growth of microorganisms. During this process, water becomes unavailable for the microbial metabolism, limiting the percentage of microbial cells that can survive. The concept of freezing can be assimilated to dehydration, as there is a block to microbiological growth within food due to the unavailability of water. The main factor that affects the size and number of ice crystals is the freezing rate. At low freezing speed, larger ice crystals can be obtained. On the contrary, a large number of small ice crystals form at high freezing speed.

In recent years, attention has focused on freezing the material as rapidly as possible, to promote the growth of large numbers of small ice crystals. There is a commercially important trade-off between the speed of freezing and the economy of the freezing operation.

Freezing process

Freezing is a thermodynamic process during which the state of the water and solutes that constitutes a given food changes from liquid to solid. By definition, a product is frozen when 80-90% of the water turns into ice.

During freezing, heat travels from the interior of the food to the surface, and is then conducted or convectively transferred to the freezing medium. Factors that influence this process are thermal conductivity, thickness, density, surface area of the food, temperature difference between the product and the freezing medium, and the resistance offered by the surface surrounding the product. In detail, the freezing process follows three phases: pre-cooling, i.e. the product is cooled to the freezing point with consequent nucleation and formation of the first ice crystals; the second step is the transition phase, where the latent heat of crystallization is eliminated; the ice crystals grow to end in the last phase, in which the product is cooled to the final storage temperature. The intermediate phase of freezing involves the conversion of water into ice through the crystallization, and it is the key step that determines the efficiency of the process and the quality of the frozen product. At a cellular level, the formation of large ice crystals causes significant damage to tissues. On the contrary, the formation of small and fine ice crystals keeps the cellular structures more intact, preserving the quality of the food.

The most consumed frozen food are meat and its derivatives, fish, greens, dairy products and pre-cooked foods. For vegetables, the cellular enzymatic activity is usually interrupted before freezing, through blanching, with pre-treatments in water or steam (70 °C - 105 °C) or with the use of additives, with the exception of food preservatives, prohibited by law.

Industrial freezing systems

The freezing methods on the market are slow, fast, very fast and ultra-fast.

The slow method involves the use of temperatures between -5 °C and -6 °C, even during storage. This is no longer used, because the very slow action of the temperature leads to chemical-physical and histological alterations of the product, causing damage to the food and also favoring the growth of ice crystals. Furthermore, it causes losses in the biological and nutritional value of foods. The fast method reduces the time to reach the required storage temperatures. Normally, temperatures between -30 °C and -40 °C are used, to quickly reach the temperature of -18 °C, which represents the best storage temperature, since there is a total stop of microbial multiplication. In the very fast method, the food is immersed in a tunnel at -50 °C and stored at a temperature of -20 °C. A few hours are needed for the temperature to reach the values required for storage. Finally, the ultra-fast method employs very low temperatures (-200 °C), obtained with liquid air, liquid nitrogen or Freon. However, this technique is not widely used yet, due to its high costs.

The main industrial freezing systems are based on:

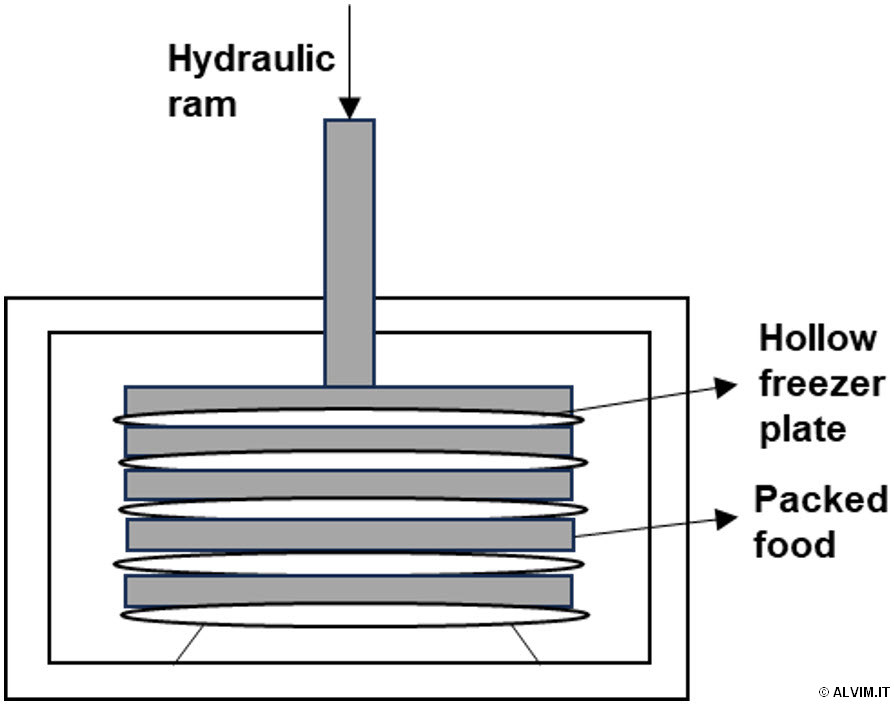

- refrigerating plates, through direct contact of the already packaged food of regular shape with cold plates, and thus indirect contact with the refrigerating fluid.

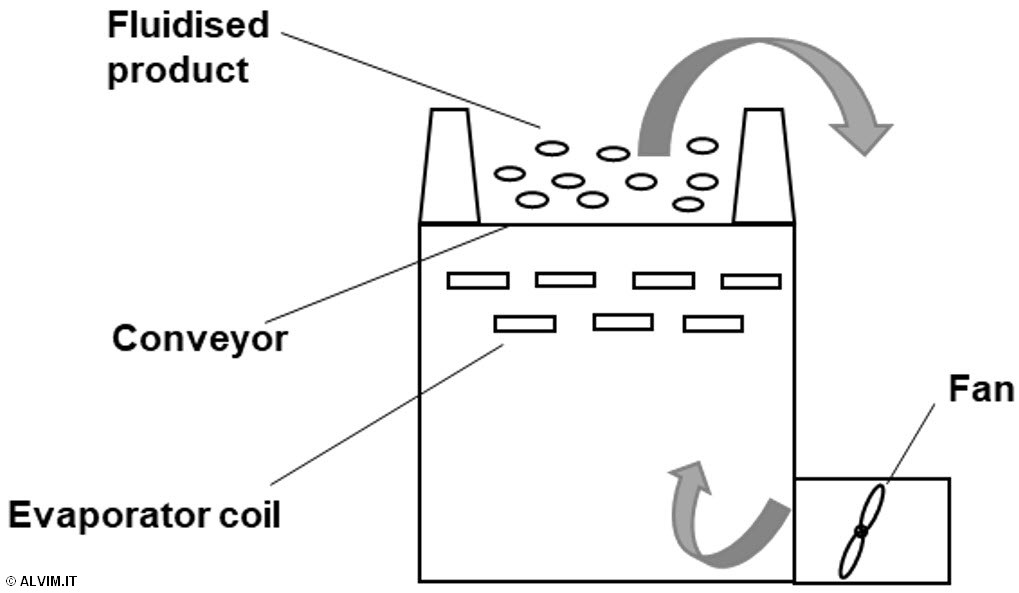

- Fluid bed or flow-freezing, where the product moves without the aid of moving parts, but is kept in suspension by a jet of air that circulates through a grid, from bottom to top.

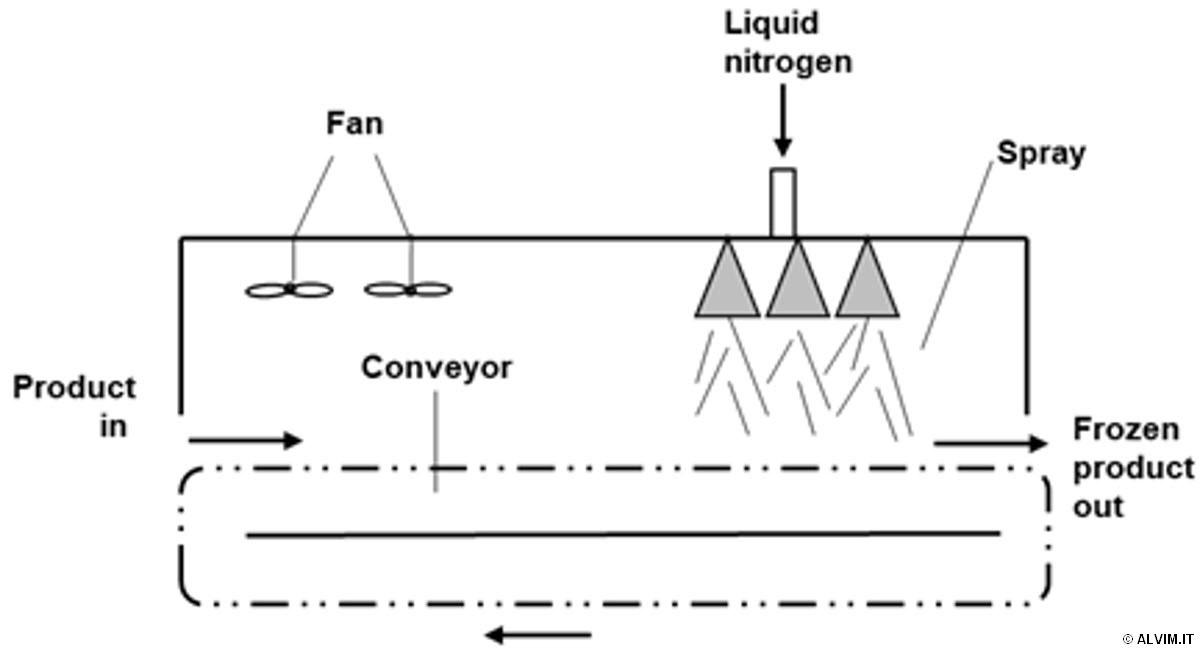

- Freezing by spraying liquefied gases (cryogenic agents), such as liquid nitrogen or liquid carbon dioxide, ideal for large-size food.

Microbial processes in frozen foods

In the production of frozen food, the attention to hygienic safety is entirely similar to that reserved for fresh refrigerated products, which from a microbiological point of view are not dissimilar to frozen ones. Although the main purpose of freezing is to preserve the quality of food with excellent results, this process also preserves the viability of some pathogenic microorganisms.

Once frozen foods are contaminated, the preparation and/or consumption patterns of these foods may further influence the occurrence of infections. When cooking instructions are not followed after thawing, or when these foods are stored for extended periods after thawing, microorganisms can grow to levels that pose a public health concern.

The most relevant factors influencing the survival and growth of microorganisms during and after freezing are freezing speed, storage temperature, storage time, food components (salts, sugars, proteins, lipids, etc.), pH, protective substances, type of packaging and defrosting temperature.

Depending on all these parameters, there can be a greater or lesser bacterial proliferation. Based on temperature, the contaminating microorganisms in food products can be different. At 10 °C we find the toxin genesis of staphylococci and Clostridium botulinum, types A and B. Between 7 °C and 5 °C the proliferation of staphylococci and Salmonella. At 3 °C the risk due to pathogenic or toxicogenic bacteria ends. Below 0 °C cryophilic bacteria can be found. Finally, at -18 °C all microbial proliferation stops. Generally speaking, gram-positive bacteria are much more resistant to freezing than gram-negative microorganisms, due to differences in the composition of the cell wall.

Psychrophilic bacteria are a type of extreme microorganisms with a minimum temperature for growth of 0 °C, an optimal temperature of about 15 °C or lower, and a maximal temperature of about 20 °C. Psychrophilic bacteria are mainly distributed in cold environments such as polar regions, alpine areas with perennial snow, ice cellars, soil and deep seas. To survive in environments with such extreme conditions (high pressure, low water activity, low nutrients and even strong UV radiation), psychrophilic bacteria present a number of adaptations, such as antifreeze proteins or cold shock proteins, antibacterial membrane molecules, increased membrane flexibility, cold-active enzymes, glycoproteins, production of outer membrane vesicles and of high levels of extracellular polymeric substances (EPS). These macromolecules, secreted by different organisms into their living environment, are multifunctional complexes mainly composed by carbohydrates, containing also proteins, nucleic acids, lipids and other substances. The EPS produced by psychrophilic bacteria play an important role in biofilm formation and modification of cell environment. Indeed, in addition to increasing cell adhesion, extracellular polymers can prevent cell damage caused by osmotic pressure and freeze-drying, and inhibit ice growth and ice-recrystallization.

Besides natural environments, psychrophilic bacteria exist in many artificial low-temperature systems, such as refrigerators and freezers. Among the psychrophilic bacteria, reported to survive in refrigerated foods, there are Campylobacter jejuni (raw chicken, unpasteurized milk), Listeria monocytogenes (raw milk, cheese, ice cream, raw vegetables, raw poultry, and meats), Yersinia enterocolitica (raw milk, chocolate, raw meats), Aeromonas hydrophila (seafood) and Pseudomonas spp. (meat, fish, and dairy products). In many cases, they can pose a serious threat to consumers' health.

Minimum temperature for growth of some potential pathogenic microorganisms is reported as 5 °C for Acetobacter, 4 °C for Vibrio, 3 °C for Clostridium botulinum, 1 °C for Listeria, 0 °C for Clostridium putrefaciens, and 0 °C for Yersinia enterocolitica. Studies have found that pathogens such as Listeria monocytogenes and Staphylococcus aureus are among the species found to survive even at freezing temperatures of -25 °C.

The problem is made even worse by the fact that bacteria settled on surfaces form communities of microorganisms surrounded by EPS, creating a micro-ecosystem where the conditions are ideal for the growth of pathogens. This is commonly known as "biofilm". Several studies report, for example, how Listeria is commonly found within biofilms in the food industry - wet processing environments are wonderlands for microorganism multiplication and biofilm development. These slimy layers form on all types of materials that can be found in food plants, including plastic, glass, metal, concrete, wood and food products themselves. Within biofilm, bacteria may undergo a significant change in physiology, with an increased tolerance to environmental stresses - freezing included - and a much higher resistance to sanitation treatments.

Sanitation Methods in the Frozen Food Industry

Improper or insufficient sanitation, during food production, processing and packaging is among the most common causes of microbiological contamination of products. For this reason, the application of HACCP is of outermost importance, as discussed in a previous White Paper.

In general, the growth of pathogens in unfrozen foods can be controlled by maintaining certain physical characteristics of the products such as pH less than 4.4, aw (water activity) <0.92 or a combination of these factors. As discussed above, bacterial growth can be controlled using the freezing process - as far as the product remains frozen.

The greatest attention in the field of frozen foods, especially frozen fruits and vegetables, is to be paid to the large volumes of water (washing and cooling) that are used in these production plants. Disinfection of such water is an essential step to reduce the microbiological risk.

In order to treat water and surfaces in contact with it, classic disinfection treatments (such as chlorine compounds, peracetic acid and others) or physical methods (such as UV-C) are applied. Suitable active substances, or a combination of several of them, shall be used.

Sanitizers containing quaternary ammonium compounds (QACs), peroxyacetic acid, iodine, or chlorine have been used to control L. monocytogenes and other pathogens. Besides being effective against different pathogens, QACs leave a residual germicidal effect on surfaces. Also, peroxyacetic acid sanitizers have been shown to be effective against different biofilms. Rotating sanitizers has been reported to provide for greater long-term effectiveness and prevention. In addition, hot water or steam can be used to sanitize racks and equipment that are difficult to clean. Using hot water or steam can also enhance sanitation efforts when addressing harborage sites for pathogens.

It has been established that the persistence of some strains of L. monocytogenes, even after cleaning and disinfection, may be related to exposure to disinfectants. This phenomenon can be explained not only by the acquisition of resistance to disinfectants, but also by the existence of niches or reservoirs in the environment not reached by disinfectants, and by the formation of biofilms and the consequent creation of protected microenvironments.

To monitor bacterial growth in frozen food production lines, including the tanks used to store washing water and the linked pipelines, ALVIM has developed an online, real time biofilm detection technology. This solution allows to improve the prevention of product spoilage and the optimization of sanitation treatments, reduce the time and costs required by such procedures. ALVIM Sensors are widely used in the food industry, in the five continents, in many different applications.

Conclusions

The study of the nature, formation, detection and elimination of biofilms on surfaces is of great importance, due to their impact as a risk factor on the onset of food-borne diseases affecting public health. The resistance of biofilms to the sanitation treatments applied in the food industry increases the risk of possible outbreaks. Within biofilm, pathogenic microorganisms can survive and proliferate, representing a threat to consumers' health. Food freezing extends the shelf life of products, but it is not a one-stop solution to prevent microbiological issues. Effective sanitation treatments are essential even in frozen food production. To this aim, biofilm monitoring is of outermost importance. Thanks to ALVIM Technology, it is possible to know in real time when biofilm starts to form, verifying the effectiveness of disinfectants and optimizing their dosage, with a significant economic advantage.

|

Do you have biofilm-related issues?

|