Clean In Place [Download this white paper as PDF file]

The quality of the final product in many industries is directly linked to the effectiveness of the cleaning process and, consequently, the presence or absence of microorganisms. One of the most practical and widely used methods for cleaning closed processing systems is Clean in Place (CIP) that was developed in 1950's as a manual procedure using a balance tank, a centrifugal pump and a connection to the system to be cleaned. CIP is mostly applied in Food and Beverage industry, due to its efficiency, safety and compliance with strict hygiene standards required in this sector. CIP helps companies to achieve and maintain compliance with the stringent regulations (by FDA, EFSA and others) providing validated and documented cleaning processes. A typical CIP philosophy in the industry is that of Scottish & Newcastle Breweries (2008): "ensure all production, processing, and packaging plant is cleaned by a standard regime and to a schedule which ensures cleanliness and microbiological integrity at all times; with minimum cost, energy, and delay to production in a manner which ensures human, plant, product, and environmental safety". Indeed, CIP is a technique used to clean the interior surfaces of pipes, vessels, process equipment, and related components without the need for disassembly. This cleaning technique is mainly applied in sectors where encrustation of surfaces inside plant pipes is a serious problem. For this reason, timely removal of deposits from process equipment is essential to prevent issues such as reduced efficiency, clogging, and contamination. For example, in the food and beverage industry, rapid and effective cleaning of closed processing systems is crucial, as production lines often undergo daily cleaning to maintain high heat transfer rates, minimize pressure drops in heat treatment units, and, most importantly, ensure microbial safety. These systems, typically composed of pipe networks, pumps, valves, heat exchangers, and tanks, are designed specifically for food processing, and CIP is the primary cleaning method employed.

Also in the dairy industry, thorough cleaning and sanitation of milking systems are vital to prevent contamination of raw milk. Since raw milk is the basis of many dairy products (liquid milk, powdered milk, cream, ice-cream, cheese, yogurt), any contamination could compromise the safety of the entire production chain. A major issue in these sectors is the formation of biofilms, communities of microorganisms that adhere to surfaces, causing contamination of products, clogging of filters, corrosion of pipes, and thus posing a threat to consumer health. Addressing fouling through regular and efficient cleaning practices is thus critical across these industries to maintain system performance, product safety, and compliance with regulatory standards. Reducing water consumption not only conserves valuable resources but also lowers the associated energy, chemical, and wastewater treatment costs. For example, a case study in the UK drinks sector demonstrated significant savings - up to 222,000 liters of water annually - thanks to more efficient CIP practices for cleaning vessels and pipes. These processes not only remove visible dirt and contaminants, but also play a critical role in reducing microbial loads, ensuring product safety, and maintaining the integrity of equipment. Throughout this process, it is crucial to identify effective strategies that optimize water consumption, enhance energy savings, and improve thermal efficiency.

CIP process

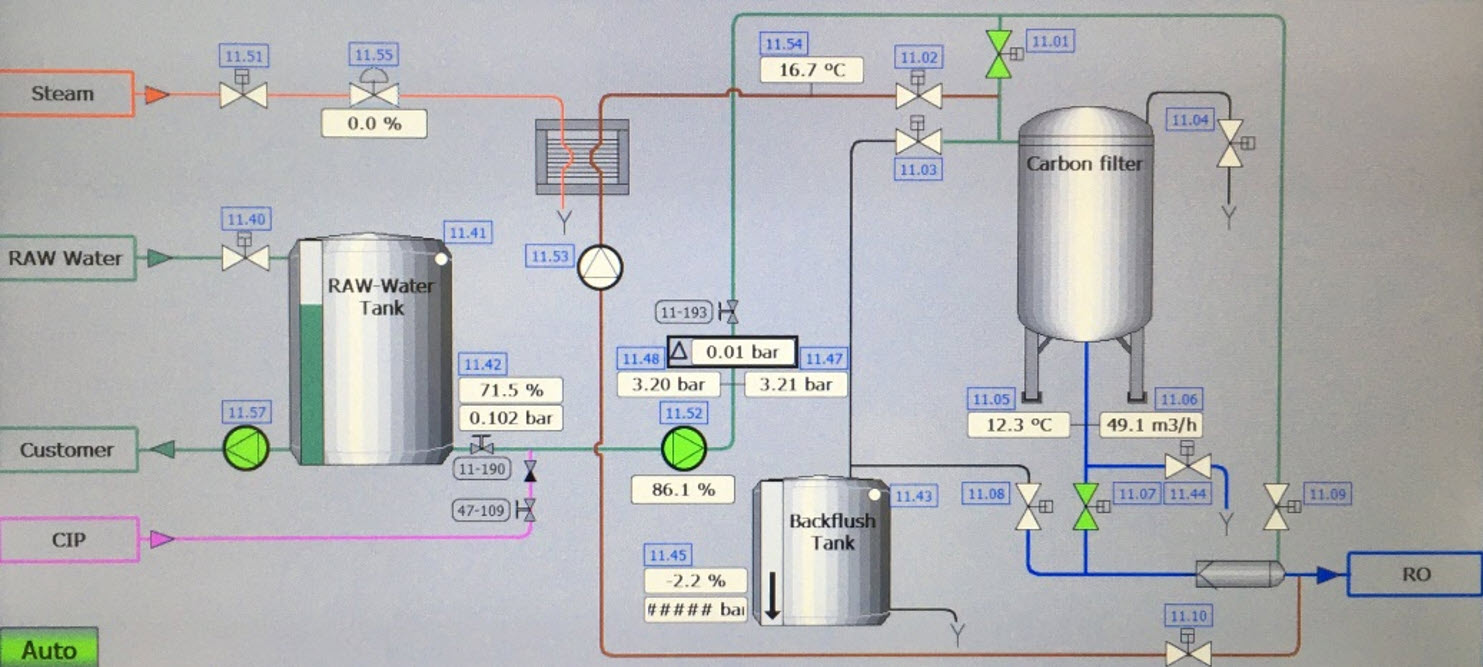

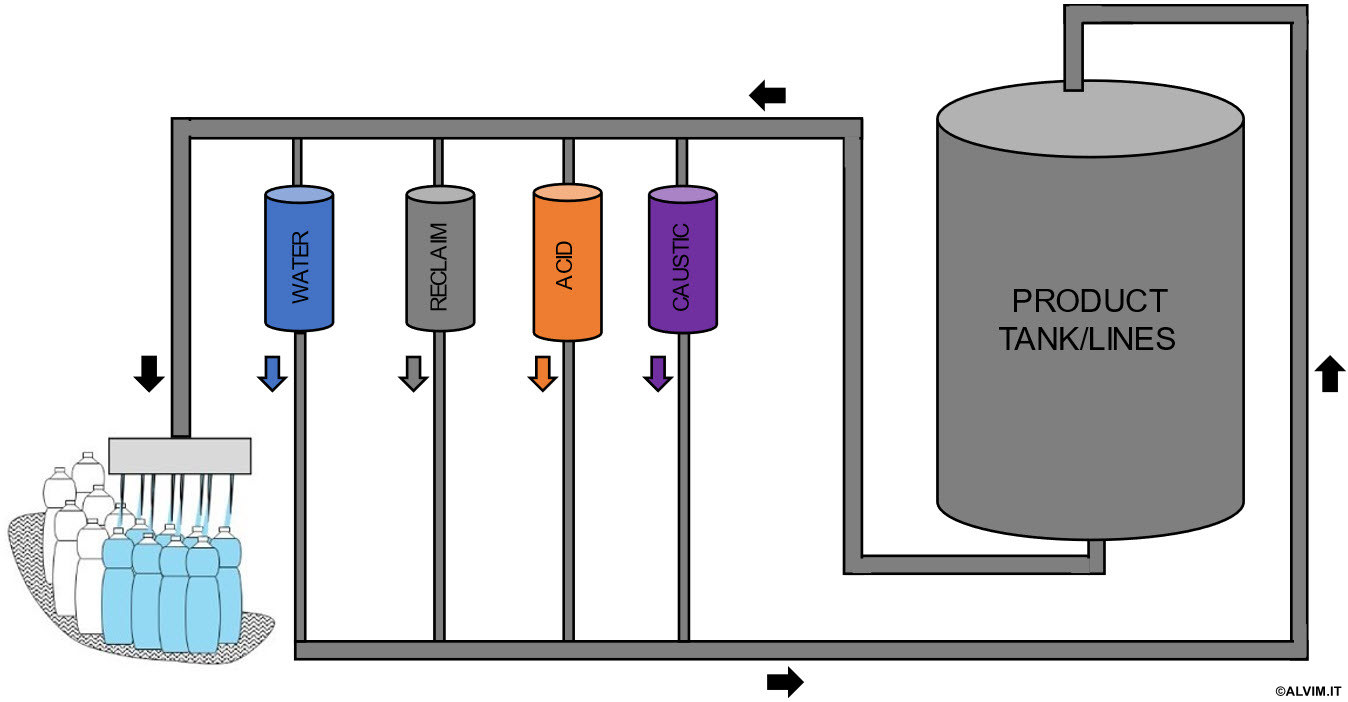

CIP involves removing contaminants such as proteins, carbohydrates, fats, and minerals from surfaces, followed by disinfection to eliminate or inactivate microorganisms. Different contaminants require specific cleaning agents and techniques: proteins and fats often need strong detergents, while minerals may require acidic cleaners. The typical CIP process consists of pumping detergents and sanitizing solutions through pipelines or spraying them onto tank walls to remove deposits. Common chemicals used include sulfuric acid, chlorine, sodium hydroxide, and potassium hydroxide, often mixed with surfactants to improve their effectiveness. A typical CIP procedure involves a warm water rinse, followed by washing with alkaline and/or acidic solutions, and a final rinse to flush out residual cleaning agents, as shown in the sequence below (see figure below):

- Alkaline cleaning: to remove organic elements

- Rinsing: to eliminate alkaline solution

- Acid cleaning: to remove mineral deposits

- Rinsing: to eliminate acid solution

- Disinfection: to kill/inactivate microorganisms

- Rinsing: to remove CIP chemicals and prepare the line for production

After the six-step CIP process, disinfection ensures that microorganisms are rendered non-viable. The CIP method uses circulating cleaning solutions through sanitary pumps, utilizing kinetic, chemical, and thermal energy to clean efficiently. For example, in the food and beverage industry, equipment like interconnected pipelines, pumps, valves, and tanks often represent challenging points to clean, highlighting the inherent complexity of CIP systems. To give an example, on a case of study the CIP system for four production lines in a large food and beverage company included 10 cleaning tanks, 9 pressure cleaning lines, and 91 cleaning circuits. The system contained 1,048 pumps/valves, 1,578 sensors, and 10 different signal types. Furthermore, it was managed by 188 types of CIP orders, 1,248 CIP formula standards, and 4,298 CIP step standards, all tailored to meet specific cleaning processes and formula requirements. These systems were controlled by precise parameters such as cleaning time, pressure, flow rate, chemical concentration, and temperature - factors collectively known as TACT (Time, Action, Chemistry, and Temperature; see figure below)

Factors influencing CIP cleaning

The removal of deposits is affected by temperature and concentration of the cleaning solution, contact time, pressure and general flow hydrodynamics. The effective CIP cleaning can be achieved when the temperature of the cleaning solution, in particular caustic soda (concentration used is 1.0 wt% NaOH), is around 55 °C - 70 °C. The pressure used with CIP inside pipelines is typically around 60 psg to 100 psg -in the case of tanks, less than 60 psg. A critical aspect of CIP effectiveness is the use of turbulent flow conditions during cleaning. Turbulent flow occurs when the fluid movement is "chaotic", characterized by rapid changes in pressure and velocity. This contrasts whit laminar flow, where fluid moves in smooth, parallel layers. In turbulent flow, the increased mixing and irregular motion create shear forces that effectively dislodge and transport residues, biofilm, or debris from surfaces. The Reynolds number (Re) is a key parameter in determining flow regime. For CIP, a Reynolds number above 4000 typically indicates turbulent flow, which is ideal for cleaning. Achieving turbulence often requires higher flow rates and properly designed piping systems, to ensure adequate velocity and pressure. Turbulent flow not only enhances the mechanical action needed to remove residues but also improves the distribution of cleaning agents, heat, and rinsing water, ensuring thorough cleaning even in hard-to-reach areas of equipment like pipes, valves, and tank corners.

Different types of CIP

There are three types of CIP systems:

- Single-use system. In a single-use system, the cleaning solution is used only once and then discarded. These systems are typically compact and positioned near the equipment to be cleaned. They are especially suitable for heavily soiled equipment, where contamination in the cleaning solution could reduce cleaning effectiveness if reused. Since the solution and rinse water are discarded after a single cycle, this approach ensures maximum hygiene, but may result in higher water and chemical consumption.

- Re-use system. A re-use CIP system recovers and recycles the cleaning solutions (detergent or acid) for multiple cleaning cycles. This design reduces chemical and water usage, making it more cost-effective and environmentally friendly. However, regular monitoring and maintenance of the cleaning solution are necessary, to ensure it remains effective and uncontaminated.

- Multi-use system. Multi-use CIP systems combine the features of both single-use and re-use systems. These systems may employ single-use solutions for heavily soiled sections and re-use solutions for less contaminated areas. This hybrid approach balances the need for effective cleaning with resource efficiency, providing flexibility based on the specific cleaning requirements of the equipment.

Based on operation, traditional CIP systems are generally divided into two types: manual systems that are based on electrical control and require human intervention, and automated systems that are controlled automatically, offering greater precision and efficiency in managing cleaning parameters. Nowadays, automated CIP is widely used and it is the standard globally for cleaning of process equipment, especially in the dairy industry. In both types, real-time monitoring of parameters such as flow rate, chemical concentration, and temperature is crucial to maintain cleaning effectiveness and ensure compliance with hygiene standards. An increasingly popular cleaning method today is the single-phase CIP, which uses either acidic or alkaline products whit chelating agents. Reacting with calcium and other metals, the chelating agents (such as EDTA) break down the deposits and facilitate their elimination. This process reduces the necessary phases to the following:

- Initial pre-wash

- Single-phase solution recirculation

- Final rinse

For preparing alkaline and acidic solutions, raw materials like caustic soda and nitric acid are used, or formulations containing surfactants and sequestering agents that enhance cleaning cycle performance. Eliminating two steps (the intermediate rinse and the second detergent circulation) results in savings in time and water, as well as a significant reduction in energy costs for heating the washing solution and operating recirculation pumps. In both cases the negative aspects must be evaluated. Single-phase systems require the use of substances that cause non-negligible environmental problems. On the contrary, in double phase systems the consumption of water, reagents and energy will be greater.

Other cleaning techniques

In addition to CIP, many other cleaning techniques are used in the industry, including foam cleaning, manual cleaning, environmental cleaning and, in addition to CIP, Sanitation in Place (SIP). In open systems, foam is widely used for cleaning large surfaces due to its ability to adhere to vertical surfaces, providing prolonged contact time for detergents to act. Foam can penetrate hard-to-reach areas and it is particularly effective for manual or semi-automated cleaning process. Manual cleaning is used in smaller operations or for areas that are difficult to automate. This method relies heavily on operator skill and the quality of detergents used. With regard to environmental cleaning, the disinfection of floors, walls, and general workspaces are essential to minimize the risk of cross-contamination. SIP is an additional cleaning process that involves a sterilization step. Sterilization of critical sanitary processes is carried out at the end of the CIP process. This allows the microorganisms still active in the system to be eliminated with hot water or saturated steam at high temperatures (typically 140 °C). The effectiveness of this operation can be further improved by adding chemical disinfectants.

Microbiological contamination problems

During processing, food particles and other materials can accumulate on the internal, wet surfaces of equipment. This deposit may harbor microbes, compromising the safety of the final product. The primary goal of CIP is to eliminate organic deposits such as proteins, carbohydrates, fats, and minerals that provide nutrients and shelter to bacteria. The formation of bacterial biofilms in food processing plants is a significant concern for manufacturers. This slime protects resident bacteria, increasing their resistance to antimicrobial treatments and cleaning efforts. Biofilms also contribute to other operational issues, such as corrosion of metals, decrease in flow, in equipment lifetime and in heat exchange efficiency. An effective cleaning and sanitation program is crucial to eliminate microorganisms. Unfortunately, most sanitation agents are developed based on studies carried out on planktonic cells, which have physiological characteristics distinct from biofilm cells.

In this context, water quality plays a crucial role in the effectiveness of cleaning processes. The hardness of the water, its pH, and the presence of dissolved salts, such as chlorides and sulfates, can significantly impact the performance of detergents and disinfectants. For example, hard water consumes more detergent and can lead to limescale formation, which creates a protective refuge for microorganisms. Chlorides can cause equipment corrosion, while sulfates can interfere with disinfectants and encourage bacterial growth. Therefore, understanding and controlling water quality is essential to maintaining effective cleaning operation and for designing an effective CIP process

Innovative techniques to improve CIP efficiency and microbial control

Several conditions affect the efficiency of the CIP, such as physicochemical properties (pH, humidity, chemical composition) of the dirt, surface properties (hydrophobicity and roughness), temperature profile between the fluid and equipment surface, chemicals and their concentration, hydrodynamic conditions, including flow velocity, average shear stress and its oscillation, equipment geometry and the presence of stagnation zones. Computational fluid dynamics (CFD) techniques are useful to study the effects of the geometry of the piping system on fluid dynamics. Thus, it becomes possible to predict the behavior of fluids inside the pipes and risk regions with unfavorable hydrodynamic conditions for sanitizing, considering shear stress and flow variability. Additionally, the use of CFD simulation provides mathematical models used to numerically predict the behavior of the process, which contributes to reducing energy consumption, use of chemicals and rinsing water, downtime in production, and the number of effluents. A promising approach to reduce microbial adhesion is the modification of surfaces, sometimes used in food industries, with the application of cold plasma. This strategy not only has the potential to minimize the need for chemical agents, such as chlorine, in the sanitization stage, but it also contributes to inhibiting the formation of pathogen biofilms, reducing the risk of food contamination, especially in sections of piping that present areas of fluid stagnation and recirculation.

Monitoring the effectiveness of CIP

Continuous monitoring of CIP effectiveness is essential to ensure compliance with hygiene and regulatory standards. It is crucial to verify the effectiveness of sanitation to either confirm or adjust the parameters taken into consideration, as previously discussed, and to minimize contamination. The main indicators used to ensure CIP effectiveness are the concentration of cleaning chemicals, temperature control, flow rate, and the time spent cleaning. Additionally, post-CIP monitoring involves sampling rinse water that circulates within the system, and analyzing it by means of ATP and TOC quantification.

CIP processes use chemicals such as caustic soda or acids to dissolve organic and mineral deposits, as previously mentioned. The concentration of these chemicals is monitored using conductivity or pH sensors, which help to maintain optimal concentration ranges, preventing insufficient levels, that can fail to clean adequately, or excessive levels, that can damage equipment. Temperature significantly affects cleaning efficiency, as CIP systems operate at specific temperature to maximize the results. Thermocouples or infrared sensors are used to monitor temperature, ensuring that each stage reaches its target.

Monitoring the flow rate using flow meters is essential to prevent insufficient flow from causing dead zones within pipes where residues may remain. Additionally, the duration of each CIP stage, from pre-rinse to chemical wash, shall be carefully controlled, with automatic timers ensuring that each phase has the necessary contact time. Post-CIP verification is commonly applied to detect biological residues and organic material in the rinse water used in the system. The ATP method detects biological residues, while TOC quantifies organic compounds, as detailed in a previous white paper about bacterial monitoring techniques . To further verify CIP efficiency, an on-line, real-time technology has been developed by ALVIM.

ALVIM Biofilm Sensor is a high-tech solution for monitoring bacterial biofilm development in industrial systems. This device detects biofilm growth at an early stage, allowing industries to optimize cleaning and sanitation procedures, particularly in Clean-In-Place applications. Monitoring biofilm build-up, the ALVIM Sensor allows to trigger CIP just when needed, minimizing chemical and water use, while reducing production downtime, thus enhancing the overall efficiency of the system. With applications across water systems, food production, and cooling towers, ALVIM Technology supports both operational efficiency and regulatory compliance. By implementing biofilm sensors within the CIP process, operators can monitor biofilm formation in real-time and take immediate corrective actions before biofilms become established.

Conclusions

Effective management of biofilm and microbiological contamination is essential to maintain product safety and quality, preserve plant longevity and ensure regulatory compliance. The Clean-In-Place system represents an essential solution for industries such as food, beverage and milk processing, where rapid and thorough cleaning of production systems is of outermost importance, in order to prevent microbiological risks and preserve operational efficiency. However, constantly improving the CIP process through the optimization of cleaning parameters (such as temperature, chemical concentration and flow conditions) and the integration of advanced technologies such as ALVIM Biofilm Sensors offers a significant opportunity to reduce the use of water, energy and chemicals. Incorporating monitoring systems such as ALVIM Sensors allows not only to monitor the formation of biofilm in real time, but also to intervene promptly, preventing microbiological proliferation and reducing production downtime. With a holistic approach to cleaning control and sanitation, industries can achieve new standards of efficiency and safety, while protecting the health of consumers and the integrity of their products.

|

Do you have biofilm-related issues?

|